Without plastics, there would be no lightweight construction, no high-quality food packaging and no modern medical technology. Plastic waste and low recycling rates are the other side of the coin. DIN SPEC 91446 , with its clear standards and classifications for recyclates, is intended to boost the circular economy. Click here to read exactly how this is possible..

The importance plastics worldwide today can be seen by looking at the development of production volumes. While there were only 1.5 million tonnes of plastic worldwide in 1950, according to Statista, this figure increased to 368 million tonnes by 2019. The Ellen Mac Arthur Foundation even forecasts a production volume of 1600 million tonnes by 2050. The problematic nature of the material is also reflected in figures: according to the OECD Outlook for Plastic 2022, the world produces twice as much plastic waste today as it did two decades ago. Most of it ends up in landfills, incinerated or in the environment — for example in the oceans. Only 9% is successfully recycled.

The low recycling rate results from a fundamental dysfunctionality of the plastics markets: high-quality recyclates are on average more expensive than virgin materials. One important reason for this is the lack of recognised standards and classifications for recyclates based on reliable data. DIN SPEC 91446 “Classification of plastic recyclates by data quality levels for use and (internet-based) retail” closes this gap. The new DIN SPEC provides for the classification of recyclates according to defined data quality levels (DQL). It introduces a uniform methodology for the identification and labelling of recyclates while providing instructions for the uniform specification of plastic waste. In this way, the new DIN ensures that suppliers, retailers, recyclers, disposers and plastics processors speak the same language.

The data quality system

Clarity at a glance

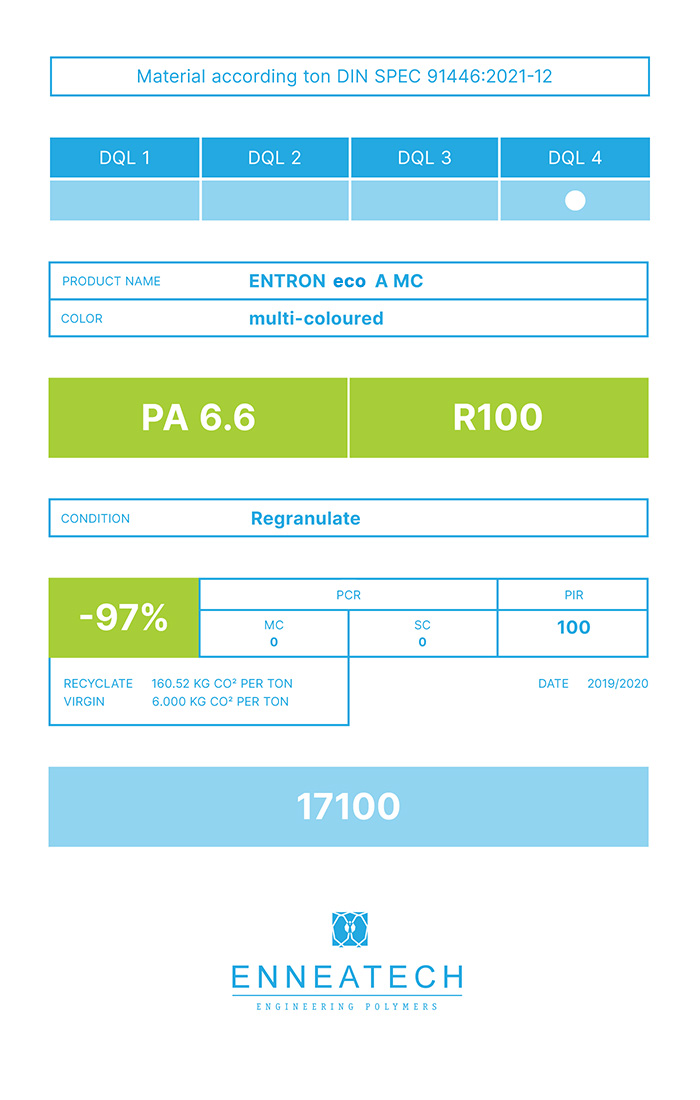

If the product data sheet and the assignment to a DQL according to DIN SPEC 91446 are available, this should be recognisable at a glance. The remedy of choice is a clearly visible label on the material packaging. This ensures that the most important facts are immediately recognisable: data quality level, material, recycled content, composition, origin (post consumer or post industrial recyclate), CO2eq, colour and more.

And this is what the label should look like:

The material information based on the new DIN SPEC 91446 provides a reliable basis for all stakeholders along the value chain. Processors thus know what they are using, retailers know what they selling and recyclers know what information to provide. This is intended to boost acceptance for greater use of recycled materials in products.