To produce high-quality recycling-based PA granules and PA compounds, it’s necessary to look at the composition of both the incoming goods and end product – so a quality control in the laboratory. That’s why ENNEATECH’s laboratory specialists completely analyse the fibres supplied and the company’s end products. As standard, our laboratory staff examine raw materials and the PA granulates produced for melt range, viscosity, moisture, ignition residue and, for a year now, also qualitatively with an FR-IR spectrometer.

With the new compounding line for producing glass-fibre-filled compounds, our laboratory equipment was further expanded considerably at the beginning of 2022 for the quality control. In addition to moisture and ignition residue determination, the mechanical parameters of the compounds are important here. These are indispensable for the mechanical design of components, and strength calculations. Designers need the following values: tensile strength, elasticity modulus, impact strength and notch impact strength.

Tensile strength indicates the maximum load-bearing capacity of a material. In contrast, impact strength describes the ability of a material to absorb shock and impact energy without breaking. Notch impact strength indicates how resistant a material is to any abrupt, dynamic stress. Elasticity modulus reflects the relationship between strain and stress during deformation. The higher the elasticity modulus, the more the material resists deformation. A plastic component with a high elasticity modulus thus has a higher rigidity than an identical plastic component with a low elasticity modulus.

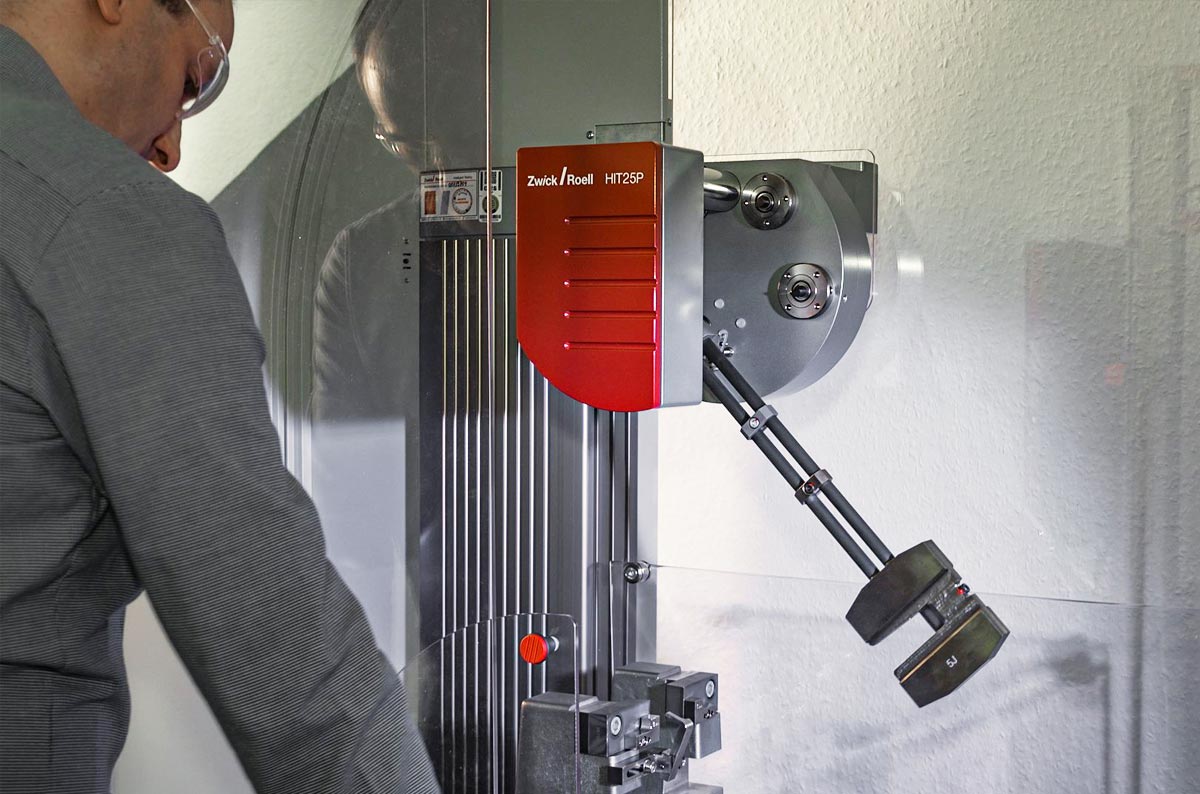

Therefore, mechanical parameter data are must-haves for compounds. That’s why, necessary metrological equipment – all from ZwickRoell – have been part of Enneatech’s laboratory for over a year. Our staff use a tensile testing machine to test tensile strength, strain and the elasticity modulus of both the test specimens and the PA fibres used to reinforce concrete. The impact pendulum with a notched plane measures the impact strength and notch impact strength of the test specimens. The latter are produced on the injection moulding machine – also purchased in 2022 – an Arburg Allrounder Golden Edition with a clamping force of 500 kN.

In addition to the mechanical parameters, ENNEATECH also determines the glass fibre length distribution, because this also affects the mechanical properties of the compounds. The flow behaviour of the compounds is represented by the melt volume flow rate MVR.

Quality control of the filled compounds is indispensable. They are used to produce sensitive components for the automotive and construction industries. Here, high mechanical strength and seamless production control are indispensable.

Seamless control

Speaking of seamless: our staff continuously take samples of both granulates and compounds, and examine them carefully using our measuring instruments. Our company also removes samples of finished compounds from each container to check the quality and collect reserved samples. Throughout the year, our team also collects samples of granulates and compounds. These finally go to external testing, where they are tested for hazardous substances according to RoHS, REACH, POP, and also TSCA for the USA.

ENNEATECH believes that extensive testing procedures and controls are important, so that we can prove that sustainable recycling-based PA granulates and PA compounds with outstanding mechanical properties are a reality.

By loading the video, you agree to YouTube’s privacy policy.

Learn more