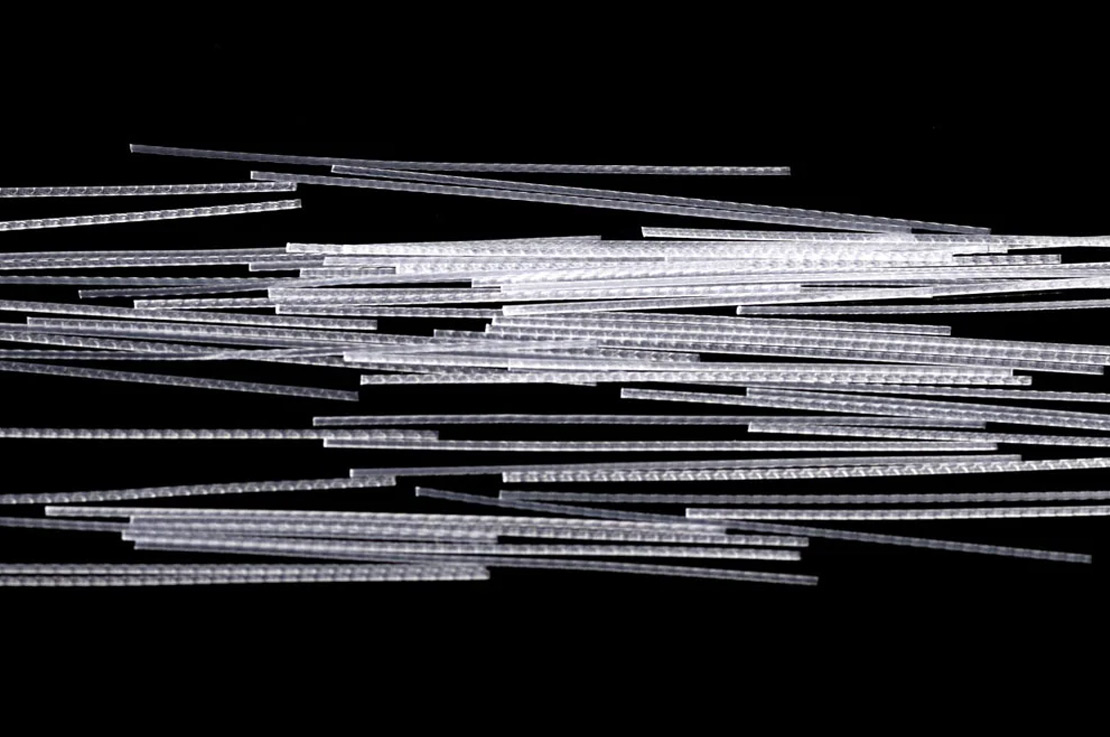

Concrete slabs reinforced with polyamide fibres instead of steel reinforced concrete — this is the decision faced by the builders of a sports complex in Dubai. The buildings of the sports facility have to withstand heat, sandstorms and the aggressive climate by the sea. The wall panels of the buildings could be created without conventional steel beams. Instead, Dubai officials plan to focus on ENNEAFIL macro and micro fibres. The fibres provide high impact and abrasion resistance, prevent cracking, increase resistance to explosive spalling of the concrete in the event of a fire, increase resistance to plastic shrinkage during hardening of the concrete wall and improve its structural strength. Particularly charming: The ENNEAFIL fibres do not corrode, even if they wait longer at the construction site. And: They are much lighter than steel. This simplifies transport and handling and reduces energy requirements throughout the entire logistics chain.

The proportion of ENNEAFIL macro and micro fibres varies from application to application, because it depends on the individual demands. In determining the optimum composition, ENNEATECH assists its customers with its know-how and experience in material science and fibre reinforcement and carries out the necessary technical calculations in accordance with international guidelines. ENNEATECH is therefore more than just a material manufacturer, because the Enneatech team analyses the project requirements with the customer and develops the optimum ENNEAFIL concrete mix based on this. In the case of the sports complex, 0.21 weight percent macro fibres and 0.021 weight percent micro fibres would be used. 1 kg of ENNEAFIL fibres would replace around 6.5 kg of reinforced concrete here to withstand the required design loads. The consequence is obvious: The ENNEAFIL-reinforced walls are corrosion free and significantly lighter and therefore easier to handle and transport.

The polyamide fibres only give the concrete its good mechanical properties if the fibre-concrete adhesion remains high and the distribution of the fibres remains homogeneous throughout the entire processing procedure. Intensive research efforts have paid off. ENNEATECH has developed a very special design of fibres to ensure adhesion and homogeneous distribution. In addition to the good mechanical properties, ENNEAFIL also stands out due to its significantly lower CO2 footprint compared to reinforced concrete. Enneatech’s calculation of the CO2 footprint of the fibre-reinforced concrete walls is always part of the overall package.

In addition to the sports complex in Dubai, ENNEAFIL has already proven itself in similar applications in other Gulf states.

By loading the video, you agree to YouTube’s privacy policy.

Learn more